Impression Trays Introduction

An impression tray is a device which used to carry impression material while making impressions. They are available in various designs and configurations. They are available in predetermined sizes and can be individualized for particular patients. This chapter presents information on various types of impression trays and their indications.

Table of Contents

Impression Trays Definition

Impression Tray:

A device used to carry, confine, and control the impression material while making the impression.

Read and Learn More: Preclinical Prosthodontics Notes

Impression Trays Ideal Requirements

- Impression trays must be rigid. Flexible trays cause distortion of the impression.

- It should be dimensionally stable.

- It should provide uniform space for impression material.

- It should be smooth to avoid injury to the oral structure (borders and joint of handle and tray).

- It should not distort the tissue in the vestibular area.

- It should support set material when removed from the mouth so that a cast can be poured.

- If needed, it can be modified by a dentist.

Impression Trays Classification

Impression trays can be classified according to their availability, use, and material used to fabricate it.

According to Use:

- Stock/prefabricated

- Custom/special tray/individualized tray

- Sectional tray/quadrant tray

- Triple tray.

Stock/Prefabricated Impression Trays:

These are available as readymade sets of impression trays. They are available in different sizes. The size of the stock tray is designated by a number. Stock trays are available for making edentulous and dentulous impressions. They are available as perforated and nonperforated trays. They are available in metal and plastic materials. The metal trays can be used several times in different patients after sterilization. Plastic trays are usually of disposable variety. However, autoclavable plastic trays are also available. Stock trays are rigid and dimensionally stable.

Impression Tray Definition

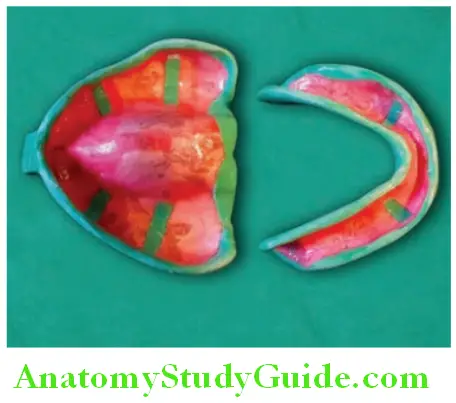

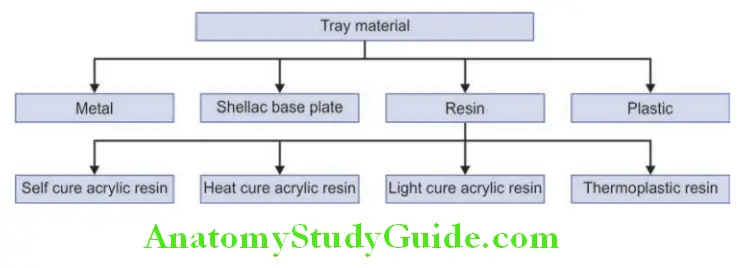

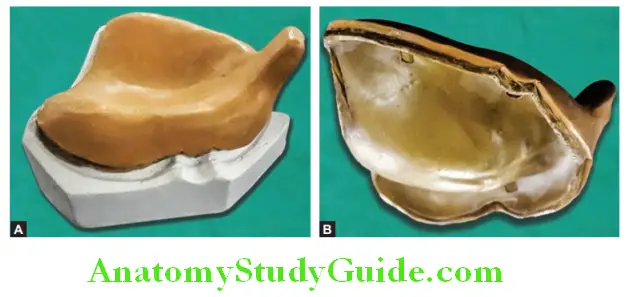

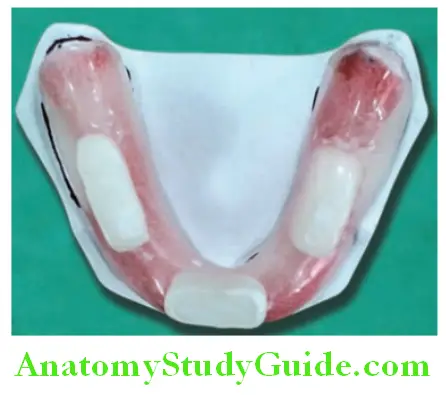

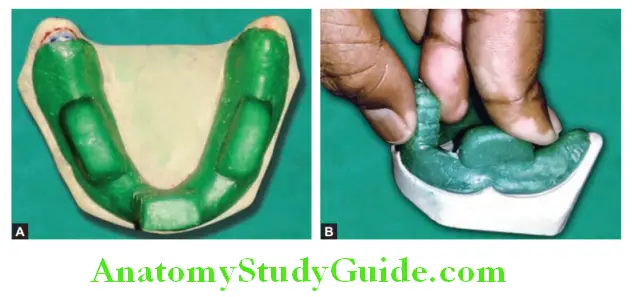

Custom/Special Tray/Individualized Tray:

These trays are specially prepared to be used for a particular patient only and cannot be used for any other patient. It is fabricated on the primary cast. It can be fabricated with self-cured polymethyl methacrylate acrylic resin, heat cure polymethyl methacrylate acrylic resin or light-cured acrylic resin, thermoplastic resin, and shellac. Most commonly, modified self-cured acrylic resin known as “tray material” is used for the fabrication of custom trays. “Tray material” is self-cure polymethyl methacrylate resin modified by adding filler particles. Most commonly added fillers are french chalk or pumice. Custom trays made up of “tray material” have less polymerization shrinkage, better fit, and adaptation. Custom trays should be 2 mm short of the sulcus as they will be used for the border molding procedure. Tray extension can be modified accordingly.

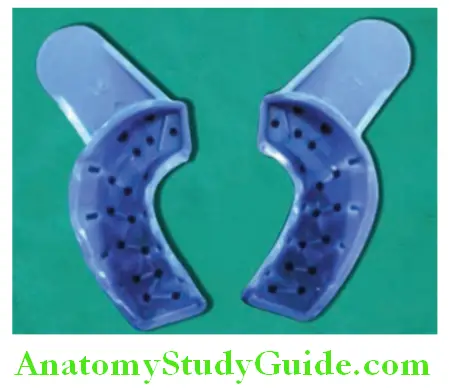

Sectional Tray/Quadrant Tray:

They are perforated trays made up of plastic or metal. They are available for the anterior quadrant, right posterior quadrant, and left posterior quadrant. They are used to make a sectional impression of a quadrant. They are usually used for making provisional or temporary restorations (temporary crown and bridge) and for making check cast impressions. They can also be used for making impressions for single tooth restoration.

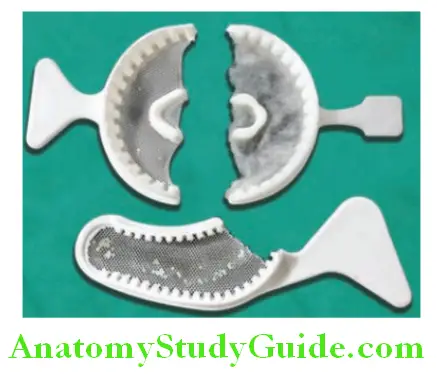

Triple Tray:

These trays are used for making impression in fixed prosthodontics. These are trays with thin mesh or net on which impression material can be loaded on both sides. With this tray, impressions of teeth to receive prosthesis (prepared teeth), teeth opposite to prepared teeth, and interocclusal records can be made simultaneously. This way it gives three records together. Hence, it is known as a triple tray. It is used for single-tooth restoration or provisionalization.

Impression Tray Sizes

Based on Tray Material:

The classification of impression trays is based on the material used to fabricate them.

Stock Trays:

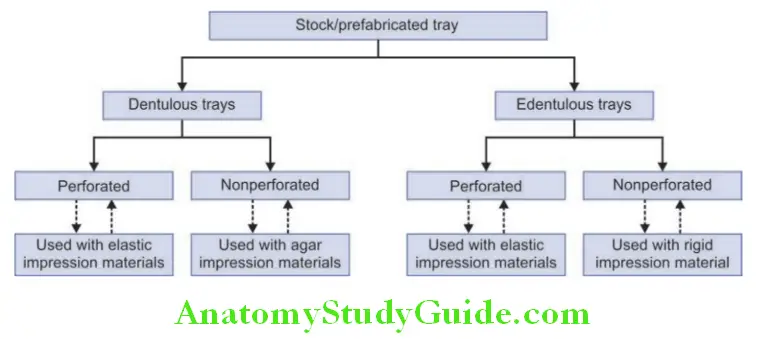

Classification of stock trays.

Perforated Stock Trays:

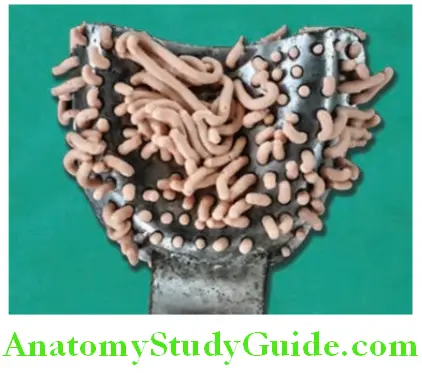

Available for making an impression of the edentulous and dentulous arch. These trays have perforations all over. Perforations allow excess material to flow out. Excess material coming out from perforations gets entrapped and serves as mechanical locking of impression material with impression tray, thus preventing separation. These trays are used with elastic impression material which needs mechanical interlocking with the tray.

Impression Tray Definition

Nonperforated Stock Trays:

Available for making an impression of the edentulous and dentulous arch. They are used for making edentulous primary impressions. It is used with rigid impression material (impression compound). Non-perforated stock trays are also available for edentulous patients. It is used with agar impression material to make a dentulous impression. However, special water-cooled rim-locked trays are used with agar impression material.

Advantages and Disadvantages of Stock Trays:

Stock Trays Advantages:

- It is rigid and supports the impression material.

- Dimensionally stable.

- The tray is precisely fabricated and smooth so injury to oral tissue is avoided.

- Multiple use: It can be reused in several patients after sterilization.

Stock Trays Disadvantages:

- An accurate impression is difficult to make as it is not an individualized tray.

- Uniform space is not available for impression material.

- Flange of the stock tray may be overextended or underextended.

- Difficult to relieve nonstress-bearing areas.

Impression Tray Sizes

Custom Tray/Special Tray/Individualized Tray

Individualized Tray Definition:

An individualized impression tray made on a cast recovered by pouring a preliminary impression (Primary cast). It is used for making a final impression.

Stock trays are available in predetermined sizes which can be used for making primary impressions. From this primary impression, a primary cast is made. On primary cast, an impression tray is fabricated which is known as a custom tray. The custom tray is an individualized tray and can be used for that particular patient only. The custom tray is used for making secondary or final impressions.

Various Materials Used for Fabrication of Custom Trays

- Tray compound

- Tray acrylic (Modified auto-polymerizing acrylic resin)

- Shellac base plate

- Vacuum-formed thermoplastic resin sheets

- Old dentures can also be used as a custom tray

- Light cure acrylic resin

- Heat cure acrylic resin.

Impression Tray Sizes

Parts of Custom Tray:

- Tray body

- Spacer

- Tray handle

- Tissue stops.

Advantages and Disadvantages of Custom Trays

Custom Tray Advantages:

- Dimensionally accurate impressions can be made as it is an individualized tray.

- Uniform space is available for impression material.

- Overextension or under-extension of the tray flange can be avoided.

- The nonstress-bearing areas can be relieved with the use of space.

Custom Tray Disadvantages:

- It can be used only for individual patients.

- Fabrication is time-consuming based on the material selected for it.

- Rigidity is lesser compared to metallic stock trays.

- Dimensional stability is lesser compared to metallic stock trays.

Edentulous Impression Trays

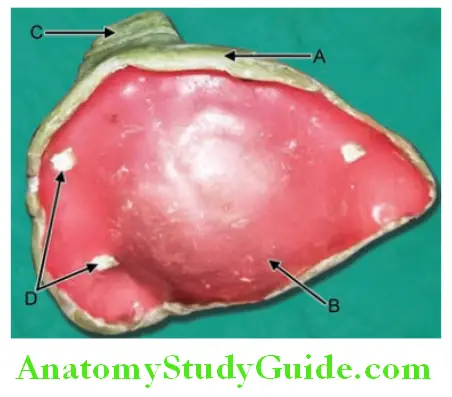

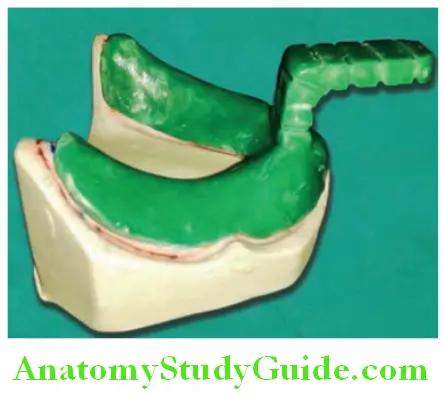

Tray Handle:

In the stock tray, a horizontal tray handle is attached to the anterior part of the tray body in both maxillary and mandibular trays. In custom trays, handles are of different dimensions and are placed at different angles than stock trays.

In the maxillary custom tray, the handle is placed on the anterior region at the midline at 45° angulation with the tray. This angulation is given to the maxillary custom tray handle in accordance with the angulation of the residual alveolar ridge and anterior teeth in the maxillary arch. The angulation also gives an idea about lip support and facilitates lip movement while doing border molding.

The mandibular custom tray handle is placed in the anterior region at 90° angulation with the tray. Sometimes two extra finger rests are placed posteriorly in the molar region to equally distribute force while making an impression.

Custom tray handles should be approximately 8 mm in length (Height), 8 mm in width, and 3–4 mm in thickness. The custom tray handle should be grooved to improve grip. Custom tray handles can be placed horizontally if needed. It should be placed in such a way that it should not interfere during border molding.

Perforations and Adhesives:

It is essential that impression material firmly adheres to impression trays. This can be achieved either by perforations or by use of tray adhesive or by a combination of both. Perforations in the tray provide mechanical interlocking between the tray and impression material and tray adhesive provides chemical adhesion. Excess impression material comes out from perforations and interlocks together to give mechanical retention between the tray and the impression material. Adhesive solutions are used with alginate, polysulfide, polyether, and silicone impression materials. Tray adhesive is supplied as a solution (applied with a brush) or aerosol spray.

Edentulous Impression Trays

Tray adhesive for alginate is the solution of resin in alcohol. Adhesive for elastomers is made up of silicone adhesive, alcohol, and colorant. The adhesive is supplied in an amber glass bottle to protect it from sunlight. After application to the tray, it is allowed to dry for 7–13 minutes before loading the impression material onto the tray

Leave a Reply