Spacer and Spacer Designs Introduction

Denture foundation area is made up of different type of anatomical structures among them some can bear the load and some cannot. During making final impression custom tray is used which should have provision to accommodate the impression materials. Spacer is used to create space to accommodate impression material in custom tray. Various materials are used to make spacer. This chapter focuses on various spacerand spacer designs for complete denture impression.

Table of Contents

Spacer In Prosthodontics

Spacer and Spacer Designs Uses

- To provide space in custom impression tray for the final impression material: Spacer is removed from custom tray after border molding. This will create space in the custom tray for final impression material.

- To selectively relieve the relieving areas: Spacer is given in areas which cannot withstand the masticatory load. So while making impression, load will not be applied on those areas as sufficient space is provided for accommodation of material.

Read and Learn More: Preclinical Prosthodontics Notes

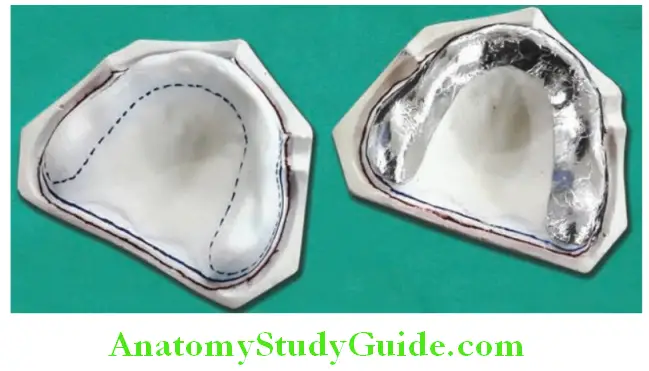

Generally double (two) spacers are given. First full spacer covering whole foundation area is placed to create space for impression material and above this second area specific spacer is given to cover specific anatomic structure to relieve that particular area or structure.

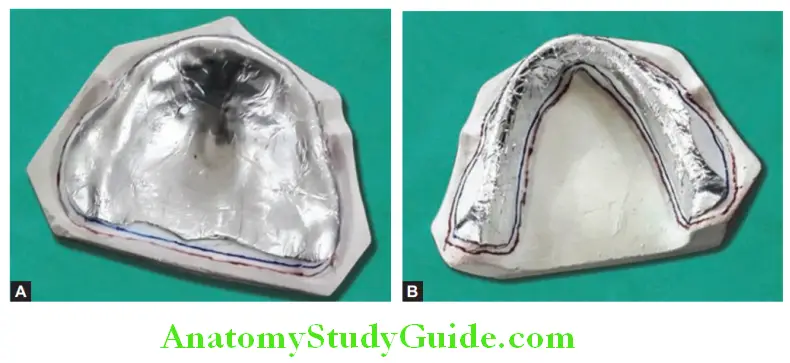

Metal foil is adapted on spacer wax for easy removal of spacer from custom tray after border molding. Metal foil helps in removal of spacer wax without any residue left on custom tray. It prevents contamination of the impression surface of the tray thus enhancing the bond of impression material and adhesive to the tray.

Spacer In Prosthodontics

Materials Used For Making Spacer

- Base plate wax/modeling wax

- Casting wax

- Major connector wax

- Metal foil.

Thickness Of Spacer

The thickness of spacer should be kept such that it provides the sufficient impression material thickness without overloading the relieving areas. Neil recommended 0.9 mm thickness of casting wax as spacer. Boucher advocates for 1 mm thickness of base plate wax while Bernard and Frank suggest 2 mm thickness of base plate wax as spacer.

Spacer Designs

Various designs proposed for spacer. Each design has its own significance. Operator can combine the spacer design according to the need of particular patient. Various spacer designs are as under.

Spacer Design by Roy MacGregor:

He proposed to adapt metal foil in region of incisive papillae and midpalatine raphe.

Spacer In Prosthodontics

Spacer Design by Neil:

Neil recommends adaptation of 0.9 mm casting wax all over foundation area. Spacer is not adapted on posterior palatal seal (PPS) area.

Spacer Design by Boucher:

Boucher recommends placement of 1 mm base-plate wax on the cast except PPS area. For mandibular ridge, all the areas except buccal shelf are covered with wax.

Spacer Designs In Complete Denture

Spacer Design by Morrow, Rudd, Rhoads:

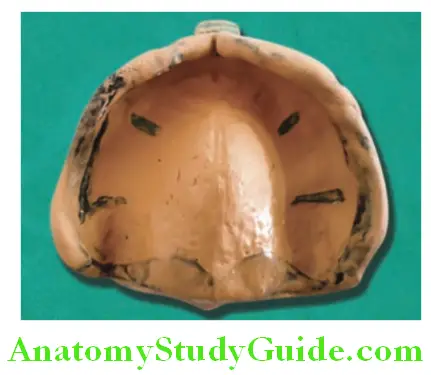

Full wax spacer 2-mm short of the resin special tray border is adapted all over. Placement of three tissue stops at equidistant from each other.

Dentures Prosthodontics

Spacer Design by Sharry:

Adaptation of a layer of base-plate wax over the whole area outlined for tray. Placement of four tissue stops (2 mm in width located in molar and cuspid region which should extend from palatal aspect of the ridge to the mucobuccal fold).

Spacer Design by Bernard:

Recommends a layer of pink base-plate wax (about 2 mm thick) attached to the areas of the cast that usually have the areas of the softer tissues. According to the present concepts, stress bearing areas in the maxillary arch are crest of the alveolar ridge and horizontal plates of the palatine bone.

Relieving areas are midpalatine raphe and incisive papilla. Taking these into consideration Shetty et al. recommend following spacer design for the maxillary arch. Sheet of wax (0.4 mm major connector wax) is placed in all the areas except the PPS area,

as this area (PPS) requires to be compressed during the border molding procedures. A 1.5 mm modeling wax is adapted on top of the already adapted wax sheet. After adapting the modeling wax tissue stops fabricated.

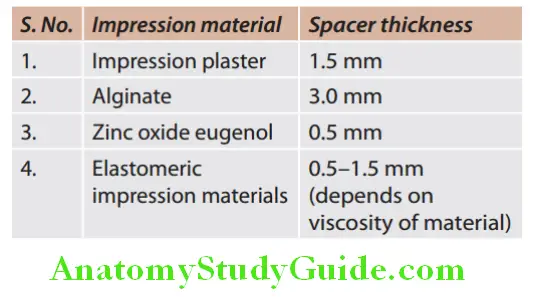

Spacer Thickness For Different Impression Material

Spacer thickness for different impression material shown in Table.

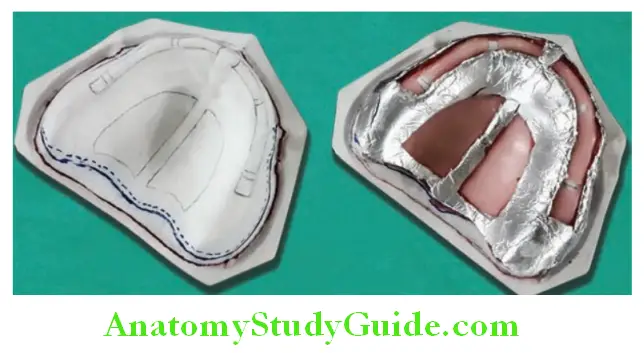

Tissue Stops

A wax spacer is applied on primary cast before making custom impression tray. This spacer wax should be cut in 2–4 spaces to create window in spacer. When custom tray is fabricated over it, part of custom tray will be in direct contact with cast through the windows. This extended part of the custom tray is called as tissue stop.

Dentures Prosthodontics

Spacer Designs In Complete Denture

Note: Tissue stop is an extension (part) of custom tray. It is not a part of spacer.

The tissue stops can be three or four in numbers. Number and location of tissue stop is critical and they should be placed far from each other to cover more foundation area. Usually four tissue stops or minimum of three stops are placed. In case of four tissue stops, two tissue stops are placed on the, canine region (one on either side) and two tissue stops are placed on molar region (one on either side). In case of three tissue stops, one tissue stop is placed in anterior region and two tissue stops are placed in molar region bilaterally.

Dentures Prosthodontics

Spacer Designs In Complete Denture

It can be square or rectangular in shape. Square tissue stops can be of 2 mm in size. The rectangular tissue stop is 2 mm by 4 mm in size (2 mm mesiodistally and 4 mm buccolingual). Rectangle tissue stops should cover the buccal and palatal slops of alveolar ridge.

Tissue stops Uses

Tissue stops helps in stabilizing and orienting the custom tray while making impression. They provide uniform space of 2–3 mm between custom tray and denture foundation and helps in free flow of material. They provide idea about thickness of impression material. They provide idea about thickness of impression material.

Note: If all four tissue stops are exposed in impression; it means they were in contact with oral tissue while impression making, the tray was stabilized and equal amount of pressure was applied all over the foundation area. If tissue stops on one side are unexposed, it means they were not in contact with tissue and impression material thickness is more in region and unequal pressure was applied by the material during impression making.

Leave a Reply