Instruments For Fixed Prosthodontics

Rotary Instruments For Tooth Preparation

Rotary instruments are used to grind the tooth (tooth preparation) to receive a crown or fixed partial denture.

Table of Contents

Mainly two types of rotary instruments:

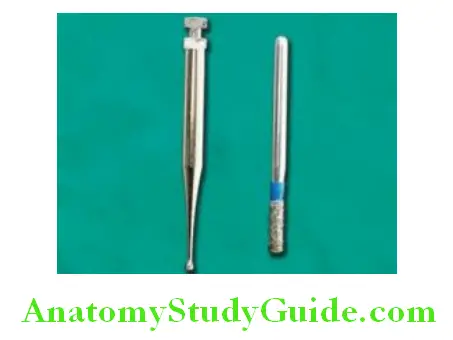

- Diamond points

- Tungsten carbide (TC) burs are used for tooth preparation.

They are available in various shapes and grits. The diamond points are classified as coarse, medium course, medium fine, and super fine and coedlor-cod as red, green, blue, and yellow, respectively. They are rotary instruments used with contra-angled handpieces. Diamond points are widely used for tooth preparation.

Read and Learn More: Preclinical Prosthodontics Notes

Diamond points to be used with micromotor handpieces and air-rotor handpieces are different. Diamond points used with micromotor handpiece have latch type nonworking end to attach it with micromotor. The diamond point or TC bur used with the air rotor has a straight nonworking end which is attached to the air rotor due to friction grip.

Diamond Points

These are commonly used rotary instruments for tooth preparation. The basic tooth preparation kit includes a straight fissure diamond, flat-end tapering diamond, rounded tapering diamond, torpedo-shaped diamond, long needle diamond, wheel-shaped diamond, and flame-shaped diamond.

Contra-Angle Handpiece

This is motor motor-driven handpiece. It gets power from an electric micromotor. This handpiece has high torque and low speed. In the contra-angle handpiece, the head of the handpiece is first angled away from the long axis and then back toward the long axis of the handle. Because of such design, the bur head lies close to the long axis of the handle of the handpiece which improves visibility and accessibility to the working field.

This design also improves stability while working. Bur or diamond points with latch-type attachment/nonworking ends are used with contra-angle micromotor handpieces.

Air Rotor Handpiece

This handpiece gives very high speed but with lower torque than low-speed handpieces. It has a speed of 250,000–500,000 revolutions per minute (RPM). The high speed is achieved by a small air-driven turbine or rotor mounted in bearing the head of the handpiece.

The sink of the bur is inserted into the rotor of the handpiece and revolves with it. The handpiece always contains a system that directs water spray at the cutting end of the bur and often also contains fiber optic light for better visualization of the operating field.

Friction Grip To Latch Converter

This is a small converter that facilitates the use of friction grip bur/diamond with the contra-angle handpiece. On one end of the converter, a latch mechanism is provided while on the other end, there is provision to attach friction grip bur/diamond with the converter.

Leave a Reply