X-Ray Film Processing And Faulty Radiographs Essay Questions

Question 1. Describe in detail film composition and explain latent image formation.

Answer: X-ray film has four basic components:

Table of Contents

- Base

- Adhesive layer

- Emulsion

- Protective layer

Read And Learn More: Oral Medicine and Radiology Question And Answers

1. Base: The film base is 0.2 mm thick and is made up of flexible, polyester (polyethylene terephthalate). It is transparent and exhibits a slight bluish tint to emphasize the contrast. The base increases the strength of the film and also supports the emulsion.

2. Adhesive Layer: The thin adhesive layer is added on both sides of the film base before the application of emulsion and functions to attach the emulsion to the base.

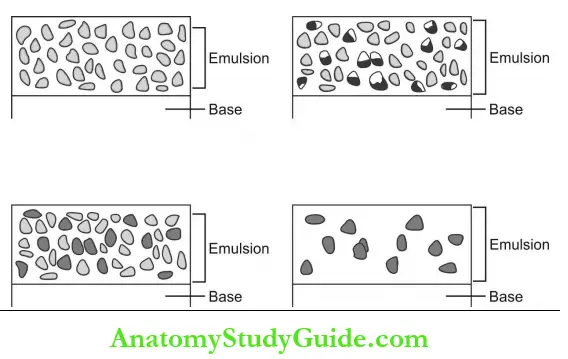

3. Film Emulsion: Emulsion is a coating attached by an adhesive layer on either side of the film. The emulsion is a homogenous mixture of gelatine and silver halide crystals.

- Gelatin: It is used to suspend and disperse silver halide crystals over the film base. During processing, gelatine absorbs the processing solutions and allows the chemicals to react with silver halide crystals.

- Silver halide crystals: These crystals are sensitive to X-rays and visible light. They are composed primarily of silver bromide and a lesser amount of silver iodide. The photosensitivity of silver halide crystals is further increased by the addition of small amounts of trace materials like sulfur or gold. The silver halide grains are flat, tabular with a mean diameter of1.6 pm in E speed film and are globular with 1 pm size in D speed film.

4. Protective Layer: It is a thin, transparent coating placed over the emulsion. It protects the surface from manipulation, mechanical, and processing damage.

Latent Image:

- The latent image is the dormant or invisible image that is formed after exposure of the film and before processing.

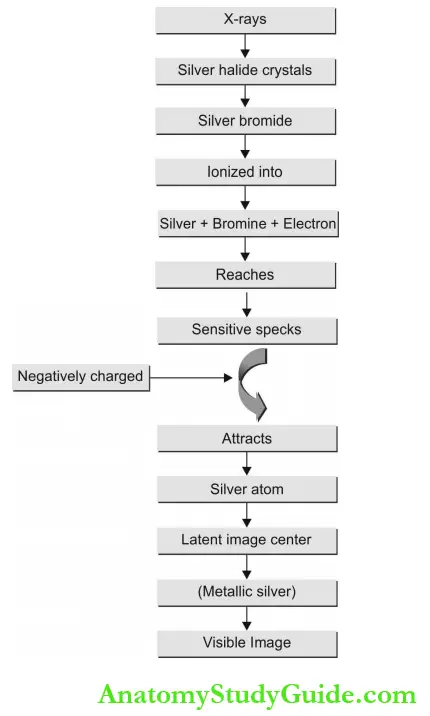

- When the film is exposed to X-ray radiation, silver halide crystals especially bromide ions are energized by the X-ray beam through Compton and photoelectric interaction.

- These crystals are then ionized by the removal of an electron from the bromide resulting in the separation of silver and bromine atoms.

- Irregularities in the lattice structure known as sensitive specks draw the free electrons and become negatively charged. Now, this negatively charged sensitive speck attracts the positively charged silver and forms neutral aggregates of metallic silver known as latent image centers.

- This process occurs many times at a single site within a crystal. The metallic silver at each latent image site makes the crystals sensitive to chemical development and image formation. The developer solution converts metallic silver sites into black, solid silver grains that can be visualized.

- A fixer solution takes away the underdeveloped halide crystals and makes the film appear plain in unexposed regions.

Question 2. Describe in detail the conversion of a latent image to a visible image.

(or)

Reveal the detailed outline of visible radio¬graphic image formation.

(or)

Explain in detail about film processing.

Answer:

- When x-rays strike the silver halides (AgIBr) film emulsion, the energy is stored in the form of the latent image.

- “Processing the film completes what the exposure started” The latent image becomes visible after the film is immersed in processing chemical solutions that change the exposed silver halide salts into metallic silver.

- Processing is the common procedure that converts an invisible image to a visible one and can be carried out either manually or automatically.

Purpose of Film Processing:

- To transfer the invisible image into visible.

- To preserve the visible image without distortion.

Film Processing:

- Manual processing should proceed in the dark room.

- During processing, the exposed film is subjected to series of a chemical reactions. The initial step in film processing is, “selective reduction”—the reduction of energized, exposed silver halide crystals into metallic silver, while the unexposed silver halide crystals are removed from the film.

- The film is placed in a chemical solution called “developer” for a specific period and at a specific temperature. The developer recognizes the exposed and unexposed halide crystals, and then reduces the exposed silver halide crystals into black metallic silver, producing dark or black areas on the film.

- Unexposed silver halide crystals remain unaffected.

- The film is immersed in water to clean the remnants of the developer solution.

- The film is next placed in a “fixer” solution for a specific time. It takes out the unexposed silver halide crystals and produces bright areas on the film.

- The black metallic silver remains on the film.

- After fixing, the film is thoroughly cleaned in tap water. This removes the remnant chemical solutions and then dried.

Visible Image: The visible image is made up of dark, bright, and shades of gray areas.

- Black areas = Deposits of black metallic silver. The amount of metallic silver varies in proportion to the properties of the structures exposed to diagnostic radiation.

- White areas = Removal of unexposed silver halide crystals.Structures that permit the passage of an X-ray beam appear black or radiolucent.

- Structures that resist the passage of an X-ray beam appear white or radiopaque.

Question 3. What are film processing solutions? Write the composition of two chemical solutions required for film processing.

Answer:

The film processing solutions are the chemi¬cals required to convert a latent image to a visible image.

They are available in three forms:

- Powder

- Ready to use liquid

- Liquid concentrate (the most commonly used type because it is easy to mix and the container occupies less storage space)

Both powder and liquid concentrate forms should be mixed with distilled water. Developer and fixer are the two chemicals used as processing solutions.

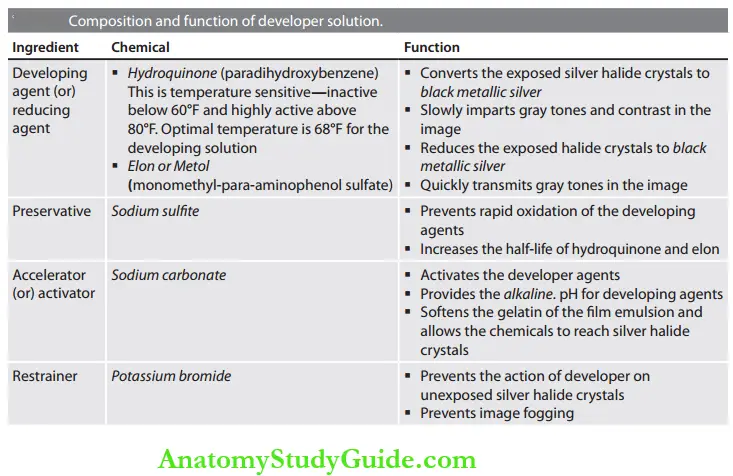

Composition of Developer Solution:

- The four basic ingredients are:

- Developing agent

- Preservative

- Accelerator and

- Restrainer.

Composition of Fixer Solution:

- The four basic ingredients are:

- Fixing agent

- Preservative

- Hardening agent

- Acidifier

Question 4. Describe the problems encountered in film processing and state the feasible solution for each.

(or)

State the possible processing errors and the remedial measures to overcome them.

Answer:

Processing errors affect the diagnostic quantity of the image by resulting in a partial or complete loss of images or unclear images of structures that are captured. Many errors are attributed to one or several causes.

Processing errors are grouped into four possible categories:

- Time and temperature errors

- Chemical contamination errors

- Film handling errors

- Static electricity errors.

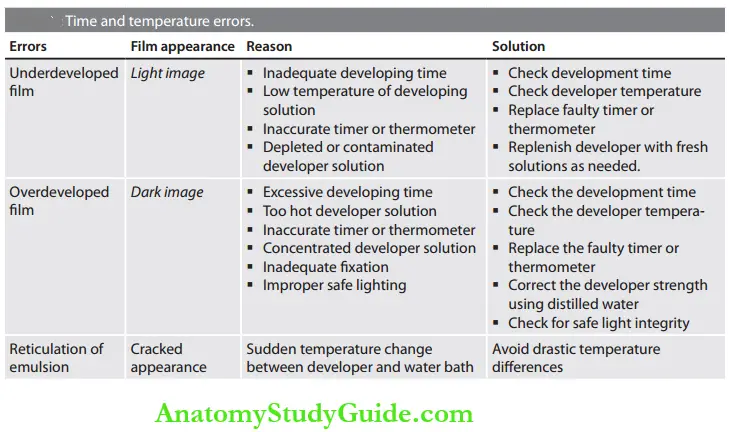

1. Time and Temperature Errors: The errors due to processing time and due to the temperature of the processing solutions are underdeveloped film, overdeveloped film, and reticulation of emulsion.

2. Chemical Contamination Errors: Developer spots, fixer spots and yellow or brown stains are the errors that occur due to chemical contamination of the processing solution.

3. Film Handling Errors: Improper handling of the X-ray film before and during exposure and at the time of film processing results in a number of errors.

4. Static Electricity Errors: Lightning marks occur on the processed radiographs either due to forcible removal of the film from the pocket or due to the excess bending of the film.

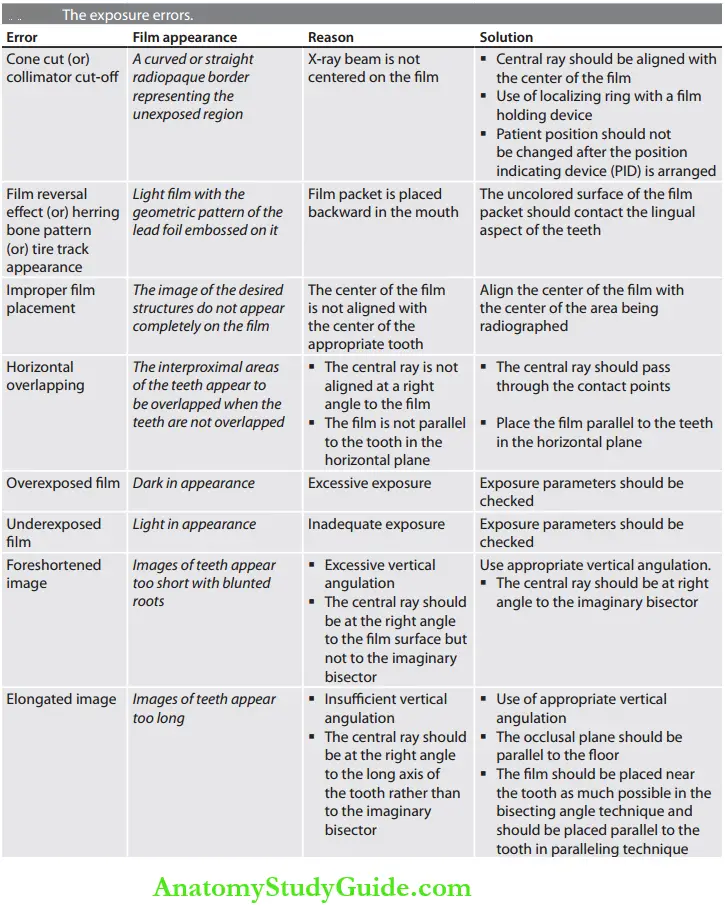

Question 5. List the possible errors that can occur due to improper film exposure and the appropriate steps to overcome such errors.

(or)

State the exposure errors that result in the faulty radiograph.

Answer: When taking the radiograph, improper exposure parameters may result in different types of errors. It is necessary to avoid such exposure errors to avoid incidents of faulty radiographs.

Question 6. What is a faulty radiograph? Enumerate the common causes of faulty radiographs.

(or)

Mention the types of intraoral radio-graphic errors.

Answer:

A faulty radiograph is one in which the diagnostic quality of the image is suboptimal or unacceptable in contrast to a typical radio¬graphic image with appropriate contrast, density, and sharp outlines.

The causes of faulty radiographs are due to:

- Developing errors

- Processing errors.

Question 7. Discuss darkroom requirements and add a note to safe lighting.

Answer: The darkroom is the place in the radiology unit where the exposed films can be handled and processed to produce diagnostic radiographs. An ideal darkroom should have:

- Convenient location

- Adequate size

- Correct lighting

- Adequate workspace and storage space

- Temperature and humidity control.

Darkroom Location and Size:

The darkroom should be in the area close to the X-ray units. It should be at least 4 x 5 feet (1.2 x 1.5 m) and should be based on the following requirements:

- The volume of radiographs processed

- Number of persons using the room

- Type of processing equipment used

- Space required for film storage.

The room should have lightproof and have good ventilation.

Lighting:

- The term “darkroom” or “light-tight room” suggests that the room might be completely dark, exclude all visible light, and no light leaks can be present.

- This is because the X-ray films are susceptible to visible light.

- Room Lighting: Overhead white light providing adequate illumination is required to perform procedures like cleaning, mixing chemicals, and stocking materials.

Safelight:

- The purpose is to provide illumination in the darkroom to carry out processing activities safely without exposing or damaging the film. It is a low intensity illumination of a relatively long wavelength in the orange-red portion of the visible light spectrum.

- Safelight consists of a lamp with a low-wattage (71/2-15 watt) bulb and a universal red GBX-2 filter for handling both intra- and extraoral films. The filter removes the blue-green portion of visible light and permits the passage of light only in the orange-red portion.

- The safelight must be fixed at 4 feet above the working area on the wall behind the processing tank.

Processing Tanks: The equipment required for manual processing is called a processing tank and its recommended size for a dental radiology unit is 20 x 25 cm (8 x 10 inches).

Master Tank: Consists of two insert tanks and is filled with circulating water.

Insert Tank: The master tank holds two removable, one-gallon insert tanks to hold the developer and fixer. The developer is always placed on the left side and the fixer on the right side of the master tank. The water in the master tank separates the two insert tanks.

Thermometer:

- A nonmercury thermometer is clipped to the side of the developer solution and is used to determine the temperature of the developer solution.

- The optimum recommended temperature is 68°F, and below 60°F, the chemicals work too slowly and result in underdevelopment, whereas, over 80°F, the chemicals work too rapidly and produce film fog.

Timer: A timer is used to indicate how long film should be placed in the developer, rinse water, fixer, and wash water.

Drying Racks:

- Two or three drying racks can be mounted on a wall for film hangers. Drip trays must be placed underneath the racks.

- An electronic fan can be used to circulate air and speed the drying. Cabinet dryers that circulate warm air around the film can also be used.

X-Ray Film Processing And Faulty Radiographs Short Notes

Question 1. Outline the steps of manual film proces¬sing.

Answer:

Manual film processing (hand processing, tank processing) is a step-by-step procedure of developing, rinsing, fixing, washing, and drying dental X-ray films to view the image.

- Manual film processing Developing:

- The first step is introducing the exposed film to the developer which softens the film emulsion and allows the other chemicals to reach the film. The developer converts the exposed silver halide crystals into black metallic silver.

- The optimum temperature used for developer solution is 68°F with a developing time of 5 minutes (between 68 and 70°F)

- Manual film processing Rinsing: Rinsing the film in water for 20-30 seconds removes the residual developer that clings to the film and stops the development process.

- Manual film processing Fixing: The rinsed film is then introduced to a fixer solution to remove the unexposed silver halide crystals and harden the film emulsion. The fixation time should be two times of the developing time.

- Manual film processing Washing: The film is washed in a water bath for a minimum of 20 minutes to remove all the excess chemicals from the emulsion thoroughly.

- Manual film processing Drying: Finally, the film is air dried at room temperature in a dust-free environment or in a heated drying cabinet (temperature should not exceed 120°F).

Question 2. List and describe the steps for automatic film processing.

(or)

Discuss the mechanism of the automatic film processer with its parts.

Answer:

- Automatic processing is a simpler way of processing both intraoral and extraoral films.

- The automatic processor consists of an in-line arrangement and transport mechanism that receives the unwrapped film and transfers it through the developing, fixing, washing and drying sections.

The transport system is a series of rollers driven by a constant-speed motor. The roller functions to:

- Move the film through the developing solutions

- Agitate the solution through their motion

- Press the film emulsion and force some solution out of the emulsion so that the emulsions rapidly fill again with solutions.

- Minimize the carryover of developer solution into the fixer tank

The Developer compartment holds the highly concentrated, developer solution that reacts at temperatures between 80 and 95°F. This high-temperature aids in rapid development in contrast to manual processing developer solutions.

The film is then directly transported to the fixer compartment without rinsing. The fixer solution is also highly concentrated and contains additional hardening agents. Here the film is rapidly cleared and then hardened.

Water compartment: Holds circulating water to wash the film after fixation.

- After washing, the film is transported to a drying chamber that dries the wet film using heated air.

- The whole process takes 4-6 minutes, and processed radiographs are retrieved through the film recovery slot.

Question 3. Describe film mounting methods.

Answer:

A mounting technique is required to transfer the radiographic interpretative findings to the patient’s record.

- Labial mounting method: Orientation is “from the lips”—as the dentist is looking at the patient.

- The raised or convex side of the embossed dot should face the dentist who is interpreting. By this method of viewing the film, the patient’s right is on the dentist’s left side, and the patient’s left is on the dentist’s right side.

- Lingual mounting method: Orientation is “from the tongue”—as the dentist is looking out from a position inside the oral cavity.

- The depressed or concave side of the embossed dot should face the dentist who is interpreting. In this method, the patient’s right is on the dentist’s right side and the patient’s left is on the dentist’s left side.

X-Ray Film Processing And Faulty Radiographs Multiple Choice Questions

Question 1. The temperature-sensitive chemical in the developing solution is hydroquinone.

- Elon

- Sodium sulfite

- Hydroquinone

- Sodium carbonate

Answer: 3. Hydroquinone

Question 2. “Cone-cut” in a radiographic film is otherwise called as.

- Partial image

- Collimator cut-off

- Filter cut-off

- Unexposed part

Answer: 2. Collimator cut-off

Question 3. The herringbone effect is the result of.

- Light leak

- Old film

- Contaminated processing solution

- Film reversal

Answer: 4. Film reversal

Question 4. To record the root lengths of maxillary molars, the preferred radiographic technique is.

- Paralleling technique

- Bisecting angle technique

- Bitewing radiograph

- SLOB technique

Answer: 1. Paralleling technique

Question 5. X-ray films are highly sensitive to.

- Long wavelength

- Short wavelength

- Orange spectrum

- Red spectrum

(Note: X-ray films are less sensitive to long wavelength, Orange-red region of the light spectrum, and are highly sensitive to short wavelength, a blue-green region of the light spectrum).

Answer: 2. Short wavelength

Question 6. The thermometer used in the processing tank should contain or metal.

- Mercury

- Hydrogen

- Water

- Alcohol

(Note: Thermometer used in processing tank should contain alcohol or metal).

Answer: 4. Alcohol

X-Ray Film Processing And Faulty Radiographs Viva Voce

Question 1. What are rapid-processing chemicals?

Answer:

- These are chemicals similar in composition to the film processing solution but are highly concentrated.

- They normally develop films in 15 seconds and fix them in 15 seconds at room tempera¬ture.

Question 2. Will you refer to a fast processing solution in your practice?

Answer: I will prefer conventional solutions for routine use and prefer rapid processing solutions only in emergency situations.

Question 3. What is the problem in using a rapid processing solution and tell the possible solution to correct it.

Answer:

- The image obtained using a rapid processing solution will be acceptable for immediate assessment but discolored over time. Also, the contrast will not be the same degree of conventionally processed films.

- To overcome this, rapidly processed films should be placed in a conventional fixing solution for 4 minutes and washed for 10 minutes to improve the contrast and keep them stable in storage.

Question 4. How to check for depleted processing solution

(or)

When to change the processing solution?

Answer:

- Immediately after preparing the new solution, a double film pocket is exposed to the first radiographed patient. These pocket films are processed in the newer solution, and one film is handed over to the patient, and another one should be mounted on the corner of a view box as a reference film. As successive films are processed, they should be compared with the reference film.

- When the solution becomes deteriorates, the contrast and density of the image will become inferior to that of the reference film image and is the indication for changing the solution (both developer and fixer).

Question 5. What is phalangioma?

Answer:

- The image of the distal phalanx (bone finger) seen in the radiographic image is known as phalangioma.

- This is commonly associated with the bisecting technique when the patient is asked to hold the film. They may keep the finger in front of the film instead of holding at the back.

Question 6. What is replenishment?

Answer: With the usage of processing solutions, the activity of the developer and fixer becomes slow down gradually, and their effect on the film also diminishes. To compensate for this loss of activity, replenishment of solution is done by adding a fresh developer and fresh fixer to the respective insert tank depending on the workload.

- For example, in manual processing with an average workload of 30 intraoral or 5 extraoral films per/day, 8 ounces of each developer and fixer should be added freshly per/gallon of solution per/day.

- Insufficient replenishment of developer results in loss of image contrast and that of fixer causes inadequate hardening of the emulsion.

Question 7. Why mercury-containing thermometers are not used in processing tanks?

Answer: Mercury is a toxic substance, and if the thermometer breaks, the mercury will spill out and contaminate the processing solutions.

Question 8. What is a latent image?

Answer: The pattern of stored energy on an exposed film is known as a latent image. This image remains invisible until the film undergoes processing.

Question 9. What is dimensional distortion?

Answer:

- When maxillary molars are radiographed using bisecting angle technique, distortion in the length of the roots of the molar may take place as elongation of the palatal root and foreshortening of the two buccal roots.

- Both buccal and palatal roots do not lie in the bisecting plane. Using paralleling technique will avoid distortion.

Question 10. What are the advantages of using automatic film processing?

Answer:

An automatic processor is preferred for the following reasons:

- Less processing time

- Automatically controlled time and temperatures

- Less equipment

- Less space.

The major advantages include:

- The requirement of only 4-6 minutes for the entire processing.

- Consistency in density and contrast properties.

X-Ray Film Processing And Faulty Radiographs Highlights

- Photographic film is adapted for dental imag¬ing purposes and on exposure to X-radiation which has passed through orofacial structures; a latent image is formed on the film. The subsequent chemical processing in the darkroom leads to the conversion of the dormant image into a visible image for diagnostic purpose.

- This chapter highlights the different types of dental X-ray film, the composition of the film, and proper film processing techniques with a detailed description of image formation. This knowledge will help to enhance the film handling capability and reduces film-related errors.

Leave a Reply