Endodontic Instruments Classification Notes

Although a variety of instruments used in general dentistry are applicable in endodontics, some special instruments are unique to endodontic purposes. The first endodontic file was made in the mid-1800s by Edward Maynard by notching round wires (earlier got from watch spring and then from piano wires).

Table of Contents

In the early 1900s, a variety of tools like pathfinders, barbed broaches, reamers, files, etc. were available but there was little uniformity in quality control, the taper of canal or instrument, and filing materials in terms of size and shape. 1958 was the hallmark year in the history of endodontic instruments.

Read And Learn More: Endodontics Notes

The manufacturers came together and a consensus was made on instruments and obturation materials.

Then in 1959, the following standardization for instruments and obturating materials was made:

- The formula for diameter and taper for each instrument introduced

- Formulae for graduated increment in size from one instrument to another was developed

In 1968, Jack Jacklich of Loyola University formed a group with other dentists and performed endodontic therapy. Over a period of time, he found endodontic treatment using hand instruments a tedious process and development of “the scourge of digital hyperkeratosis.” All these problems led to many innovations in techniques and instruments.

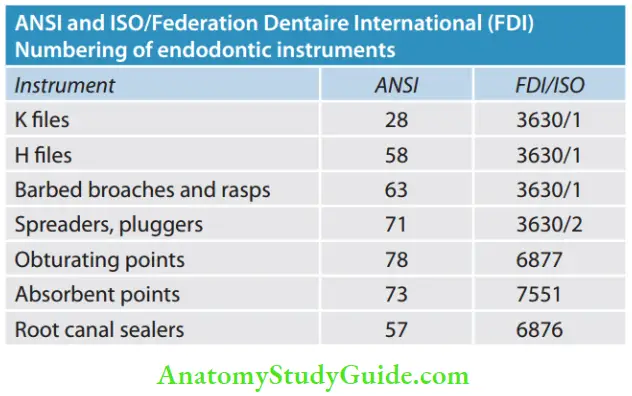

In 1989, American National Standards Institute (ANSI) granted the approval of American Dental Association (ADA) specification No. 28 for endodontic instruments.

Endodontic Instruments Classification

Standardization Of Instruments Given By Ingle And Levine

Ingle and Levine using an electronic microcomparator found variations in the diameter and taper for the same size of the instrument. They suggested the following guidelines for instruments for having uniformity in instrument diameter and taper:

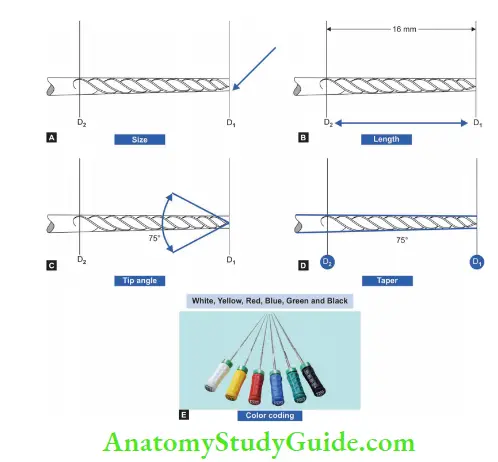

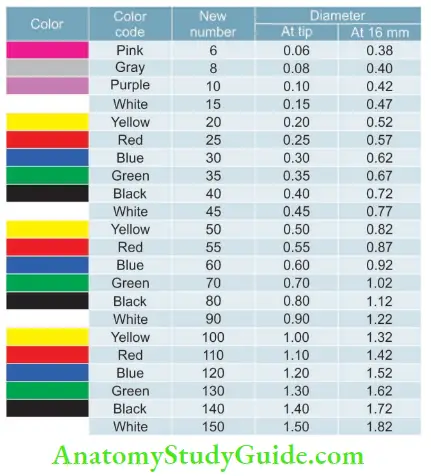

- Size: Instruments are numbered from 10 to 100. Each number should represent the diameter of the instrument in 100th of millimeter at the tip. For example, a No. 25 reamer shall have 0.25 mm at D1 and 0.57 mm (0.25 + 0.32) at D2. These sizes ensure a constant increase in taper, that is, 0.02 mm/mm of the instrument regardless of the size.

- There is an increase in 5 units up to size 60 and in 10 units till they are size 100. This has been revised to include numbers from 6 to 140

- Length: Instruments are available in the following lengths: 21, 25, 28, 30, and 40 mm. 21 mm length is commonly used for molars, 25 mm for anterior, 28 and 30 mm for canines, and 40 mm for endodontic implants

- Tip angle: Tip angle of an instrument should be 75 ± 15°

- Taper: The working blade shall begin at the tip (D1) and extend 16 mm up the shaft (D2). D2 should be 0.32 mm greater than D1, ensuring that there is a constant increase in taper, that is, 0.02 mm/mm of instrument

- Color coding: Instrument handles should be color coded for their easier recognition (Pink, gray, purple, white, yellow, red, blue, green, black, white, etc.)

Modifications from Ingle’s Standardization:

- An additional diameter measurement point at D3 is 3 mm from the tip of the cutting end of the instrument at D0 (earlier it was D1) and D2 was designated as D16

- Greater taper (GT) instruments (0.04, 0.06, 0.08, 0.10, 0.12) have also been made available.

- To maintain these standards, the American Association of Endodontists (AAE) recommended ADA and the United States Bureau of Standards to form a committee for the standardization of endodontic instruments.

History:

1750: Fauchard recommended the removal of the pulp.

1850: Wooden pegs for debriding pulp.

Early 1900: Introduction of fies, reamers, etc.

1915: Kerr company obtained a patent for their instruments.

1958: Ingle and Levine standardization of endodontic instruments.

1964: Introduction of romantic handpiece.

1975: First potential application of NiTi alloys.

1976: First approved specification for root canal instruments.

1988: First use of NiTi in endodontics.

1989: ANSI approved specification No. 28 for endodontic reamers and files.

Leave a Reply